|

|

|

DRX-2.0

|

DRX-2.4

|

DRX-3.4

|

|

Furnace effective space

|

mm

|

Φ1600*700

|

1400*1700*600

|

1800*1900*700

|

|

Rated temperature

|

ºC

|

<=1200

|

<=1200

|

<=1200

|

Induced draft motor

power

|

KW

|

5.5

|

5.5

|

7.5

|

|

Blower motor power

|

KW

|

4

|

4

|

5

|

|

Total power(Does not include gas heating)

|

KW

|

10

|

10

|

12.5

|

|

Voltage(Three-phase five-wire system)

|

V

|

380V 50HZ

|

380V 50HZ

|

380V 50HZ

|

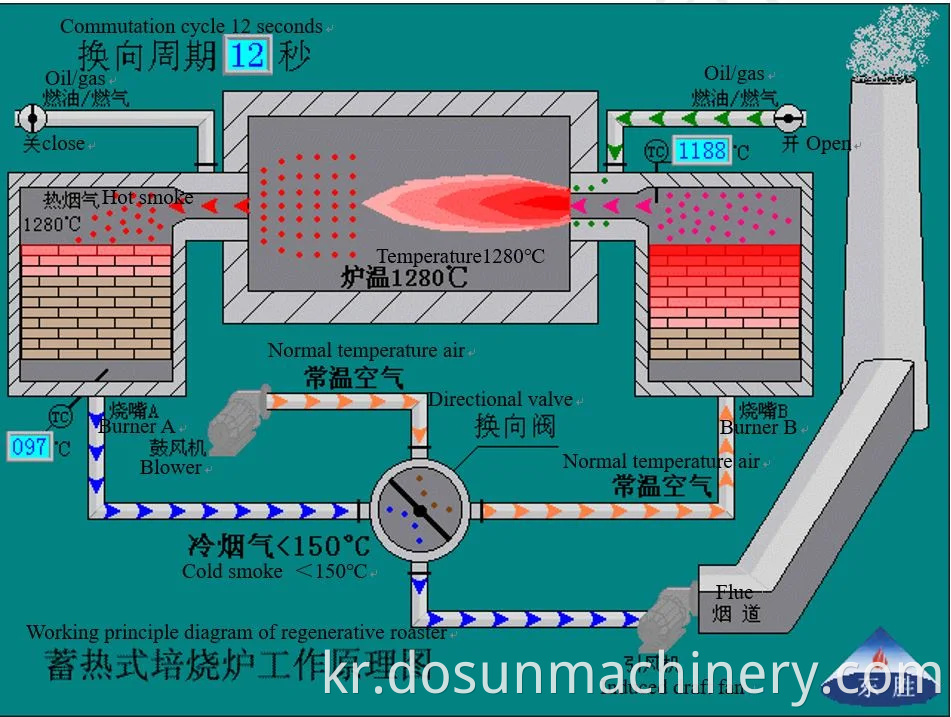

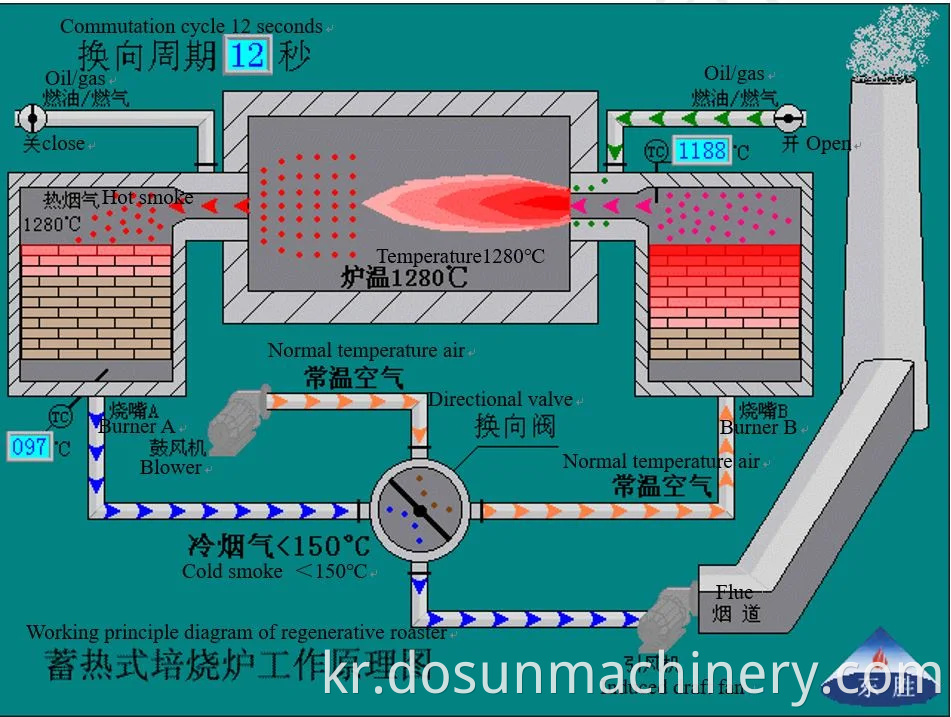

The burner heat and the effective space in the furnace can be customized according to product requirements 1. Schematic diagram

2. Structure description

Regenerative gas baking furnace shell is made of high quality steel welded together, internal and fluctuation have brace and supported to ensure the stove overall solid deformation characteristics, inside the furnace is made of high quality system of high alumina brick, brick build by laying bricks or stones, furnace shell and the furnace between filling quality insulating brick and alumina as heat insulation material, such as heat preservation cotton blanket in the furnace at the top of the high aluminum rock wool and perlite insulation materials, quality light effect is good, avoid high temperature heat affect the energy saving effect. The brick on the top of the furnace adopts the arch design to be more firm and durable. Filling high quality fiber material within the oven door and oven door is not easy to deformation of high temperature resistant, flame mouth set in the furnace with high temperature material casting, drum wind and the wind pipe is galvanized steel pipe welded together beautiful and corrosion resistance, cylinder conversion institutions have magnetic switch indicator light, each movement at a glance, temperature sensor from the top downward inserted, detection more accurate and reasonable in and out of the shell mould will not encounter damage, the control unit adopts domestic and international famous brands of the advantages of stable and reliable electrical components accurately.

3.Introduction of regenerative burner

Regenerative natural gas roaster adopts advanced regenerative burner.

In the combustion process, the fuel will discharge waste gas, waste gas will take away heat, with the increase of furnace temperature, the heat away gradually increased, flue gas heat can not be fully used.

In order to solve this problem, several organizations and technical personnel, steel plant emissions by learning experience and advantages of energy saving, development and design of regenerative burner, a new regenerative burner is the normal temperature air heating in very short time, when the high temperature of heated air into the furnace, the entrainment around the furnace flue gas to form a thin oxygen levels below 21% of the poor high-temperature air, oxygen into a thin near the high temperature air injection fuel, fuel in the lean oxygen to burn (2% ~ 20%) conditions.

At the same time, the hot flue gas burned in the furnace is discharged through another burner, and the heat of the high-temperature flue gas is stored in another burner heat storage mechanism.The commutator valve with low operating temperature switches at a certain frequency, the common switching cycle is 50-50 or 60-60 seconds .

The two burners are in alternate working state of heat storage and heat release respectively. At present, the box furnace used by most factories can exhaust smoke at more than 700 degrees, while the flue temperature of the roasting furnace is no more than 150 degrees , so as to achieve the emission effect of energy saving and environmental protection.

4.Ignition nozzle integral control structure

· Ignition nozzle inlet valve: This valve remains open at temperatures below 900 ° C.

· Pneumatic solenoid valve mainly controls whether the inlet valve is opened and closed.Click the red button of the valve body for manual switch control.

· Ignition nozzle fire hole: mainly to watch whether the ignition or extinguished.

· Ignition nozzle gas valve: the valve mainly controls the air intake to adjust the size of the flame.

5.Ignition control box ·Ignition indicator: When the ignition button is pressed, the indicator lights up, indicating that the ignition is in progress.

·Ignition button: Press the ignition button before starting the ignition gas valve and release the button after the flame burns (Note: If the ignition time exceeds 5 seconds, please repeat the ignition action).

·Foot switch: it has the same function as the lifting button of the furnace door, which is added for the convenience of operators. 6.Main burner gas stop valve

· Main burner gas valve:Gas stop valves are installed on both sides of A/B, which can control the flow to adjust the flame size. 7.Air inlet and outlet converter ·The air inlet/outlet cylinder controls the opening or closing of the cylinder over time during operation

·Smoke exhaust temperature sensor: This device collects the temperature on A/B smoke exhaust pipe and transmits it to the instrument in the control box. 8.Blower The equipment should ensure that the air inlet of the blower is normally open, and the air outlet must not be obstructed.

(Note: the fan must work in a horizontal position and must not tilt to avoid shaking damage.Tighten the locking screw after the damper is fully opened.) 9.Main burner cooling valve ·When working, the main burner cooling valve must always be kept open for air inlet, and when working or stopping the furnace, it can be kept open (Note: there are four cooling valves on both sides of this valve A/B, failure to open will lead to high-temperature damage of nozzle mechanism and so on. 10.Regenerative bulb feeder ·When adding heat storage ball, first open the flange mounting screw, lift the flange and plug at the same time.

(Note: Do not remove the flange center screw to prevent the sealing plug from falling into the regenerator) 11.Hot bulb discharge and ash discharge ·After disassembling the flange blind plate screw during cleaning, the heat storage ball will be discharged. After removing all the inner balls, it can be installed on the sealing (Note: no air leakage should be ensured between the flange and the blind plate seal during installation).

·Every time the hot bulb is cleaned, the ash chamber must be opened for ash removal.

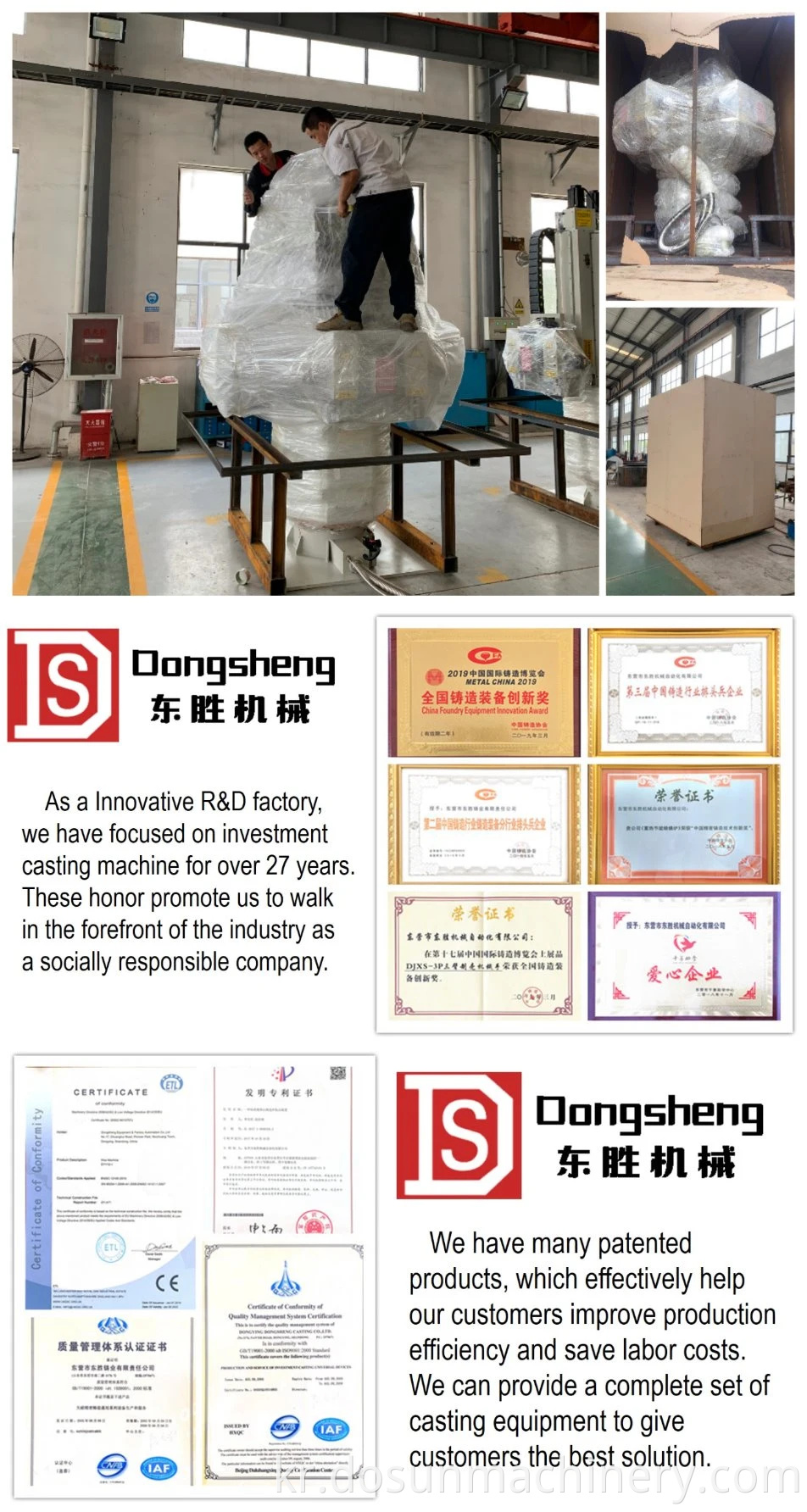

(Note: clean the ash storage room after cleaning and adding the hot bulb) 12.Transport package Packed with steel structure and MDF to ensure the safety of equipment during transportation.

About us

Founded in December 1993, Dongying Dongsheng Casting Co., Ltd. is one of the largest and earliest factories engaged in the development, development and production of precision casting equipment. The company is located in the hinterland of Shengli Oilfield in the beautiful Yellow River Delta.

According to the development requirements of precision casting enterprises, the company has determined the development concept of products with high efficiency, innovation, energy saving, environmental protection, high quality, safety and reliability, and is aggressive and striving to be in line with international standards. The company has passed the ISO9001: 2000 international quality management system certification and the EU CE certification. In May 2014, it was selected by the China Foundry Association as "the leading enterprise in the foundry equipment industry in China's foundry industry"

As a member of China Precision Casting Association, the company is willing to develop together with colleagues in the precision casting industry with first-class equipment, first-class service and first-class reputation, and create brilliant together.

We are the best vendor in the running market . Our own factory van make sure the stable shipping time and the best quality with a reasonable price. We also have the best service in the city, if u have any question, please feel free to connect with us.

|

FAQ:

|

|

Q1: How long can it be delivered after the order is placed?

|

|

Most of our machines are customize ordered, they can be delivered within 30-60 days after the order is placed;

|

|

Q2:How can I pay for the money for the machine.

|

|

We accept 30% as a deposit and the balance need to be paid by T/T before the machine shipping out.

|

|

Q3: What should I do if I find quality problems in the process of using my product?

|

|

In case of quality problems, if you need after-sales service, you can contact us through wechat / whatsapp: for communication and solution; our engineers provide 24-hour online guidance to solve the problems.

|

|

If you need to replace the parts, we will provide them to you in the first time through international express after paid.

|

|

Q4: Can I choose to buy equipment through Made-In-China company?

|

|

If you buy our products for the first time, we will fully cooperate with your choice, and you can buy them in any way.

|

|

Q5: Does the machine have an English manual and warranty card?

|

|

Each machine has a professional English operation manual. The warranty period of our machine is one year, except for human factors or wearing parts.

|

|

In addition, we can provide electronic version of the English manual.

|

|

Q6: The delivery time of products without stock is too long for 30-60 days.

|

|

First of all, we will speed production to meet your needs.

|

|

In addition, the long delivery time is because our technicians need to carefully check and debug the equipment to ensure the quality of the machine.

|

|

Q7: What if I choose the wrong machine?

|

|

We have pre-sales engineers with rich professional knowledge. According to your products, we provide the most suitable machines and solutions. Before placing an order, we make sure you don't choose the wrong machine. If it happen, we will solve the problem with you.

|

|

Q8: Who is responsible for the installation and debugging of the machine I purchased?

|

|

We the seller are fully responsible to send our engineers within two weeks from the date of the containers arrival to the buyers factory to commissioning the machine and training the staff of the buyer, the buyer should be responsible for a round trip economy ticket, a hotel and any other necessary accommodations for the seller's engineers.

|